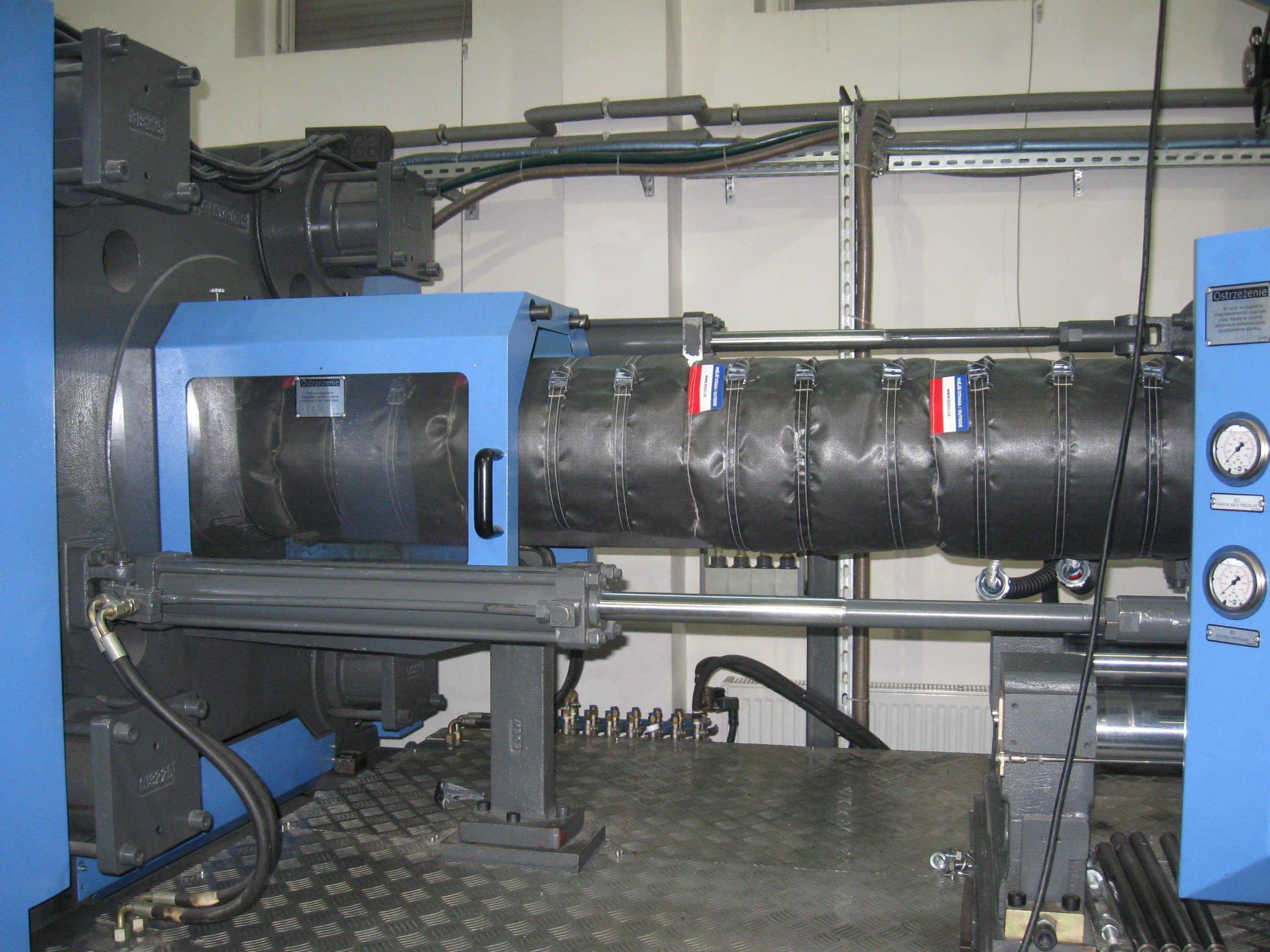

In the production of plastic products with using the injection moulding machines, the working parts of the machines (barrels, screws) are tempered to the requested temperature for the processing of the specific material. As these are usually continuous operations, the cost for energy needed to temper the machine is a significant part of the production cost.

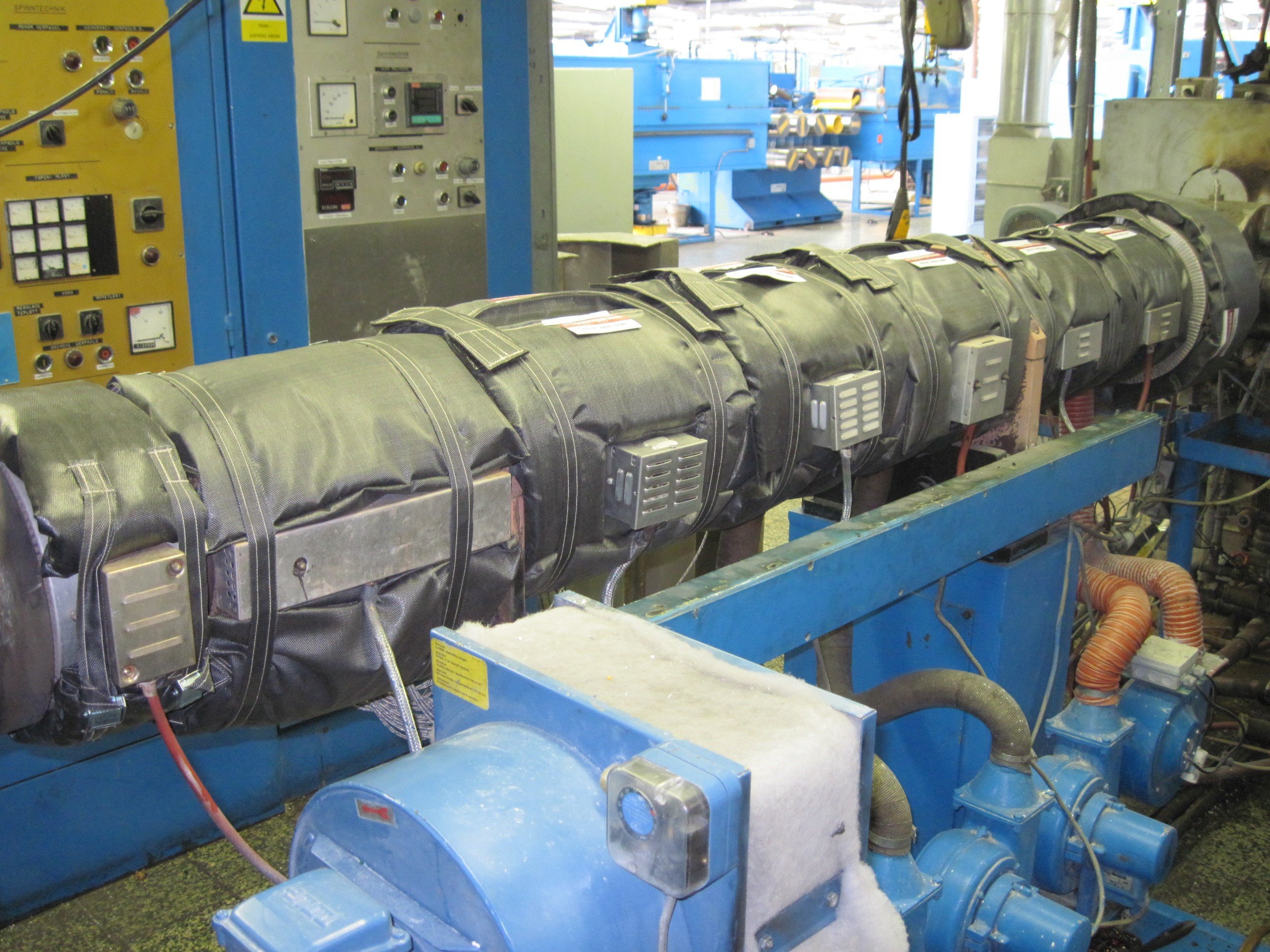

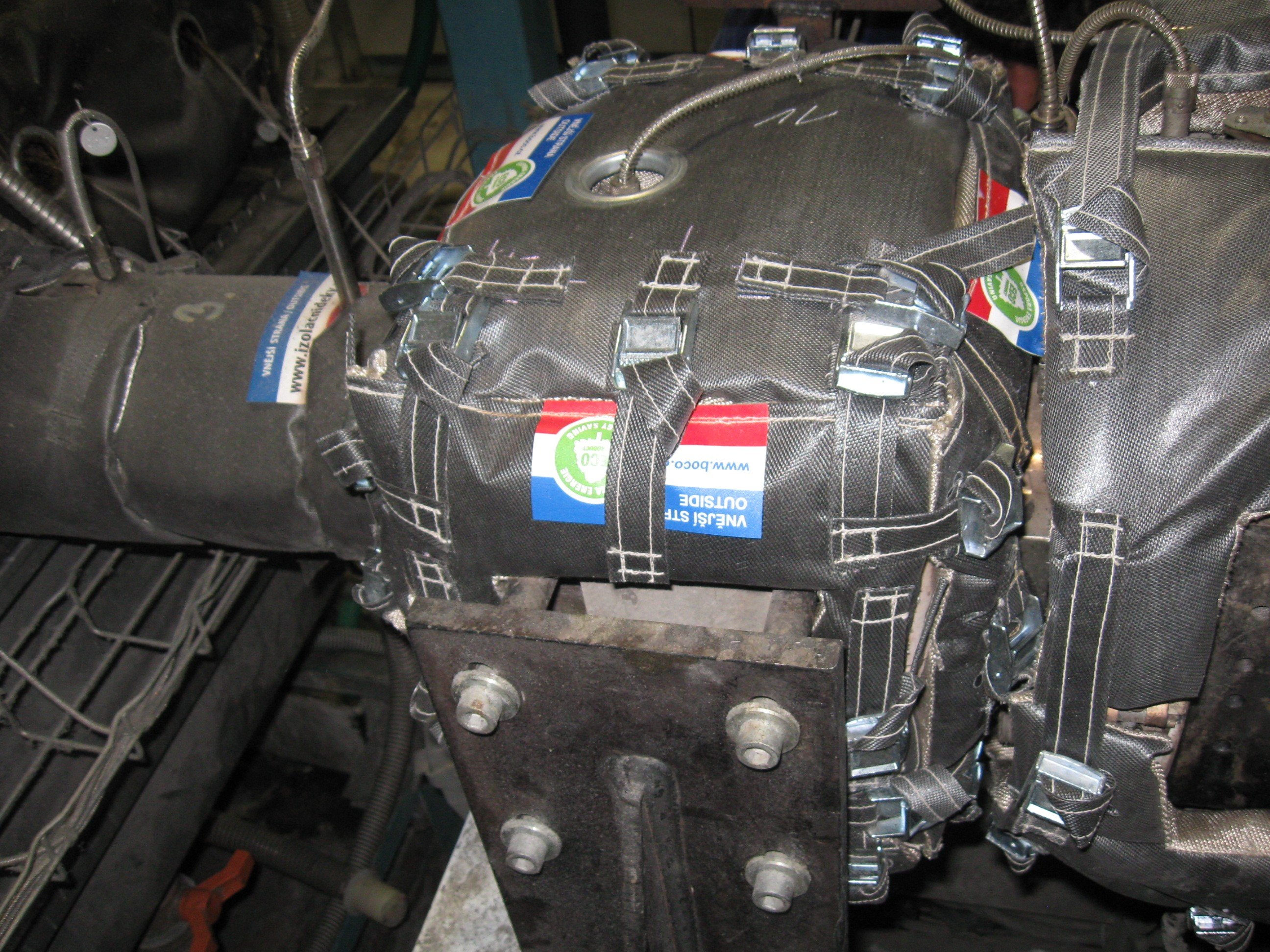

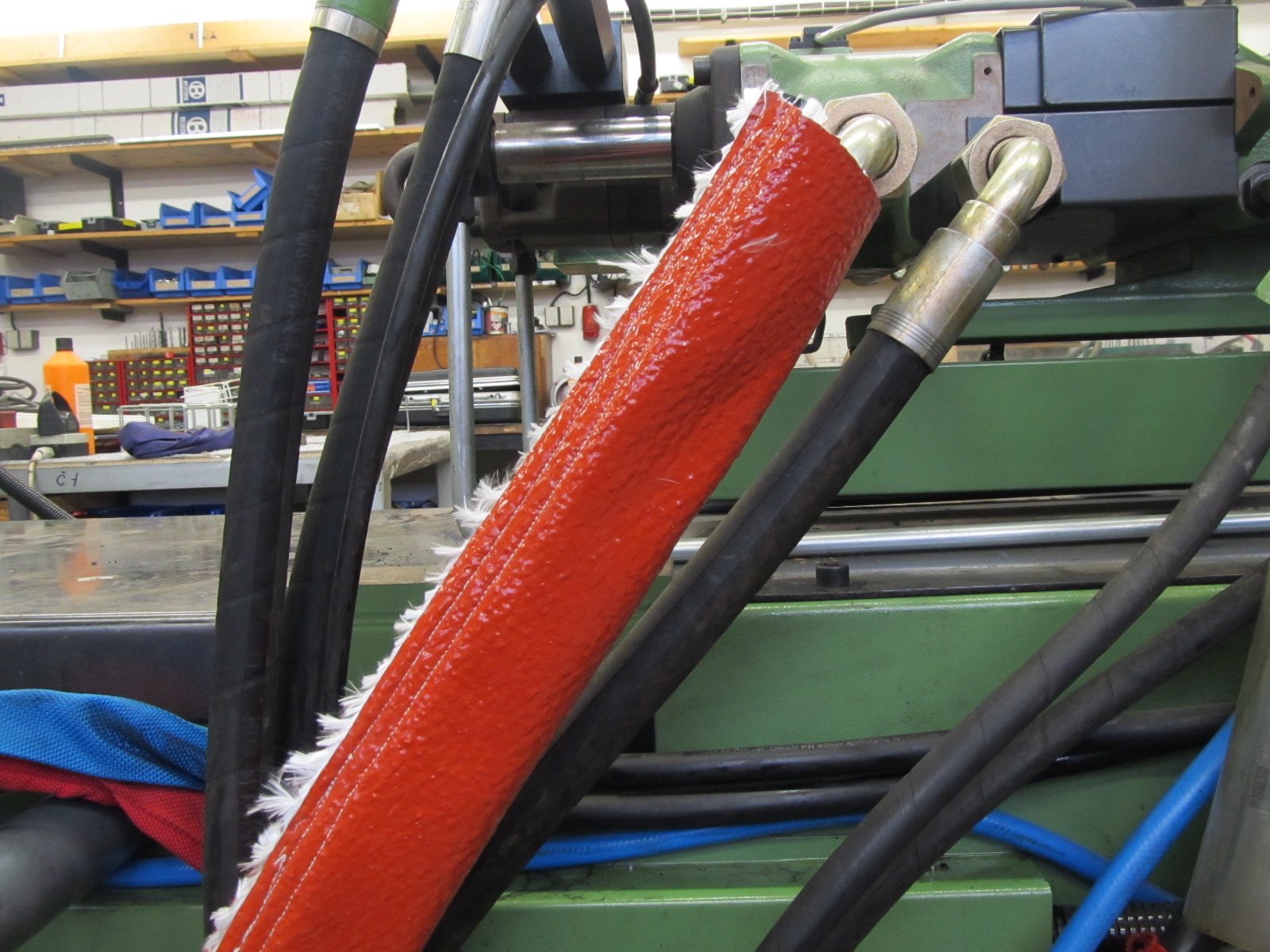

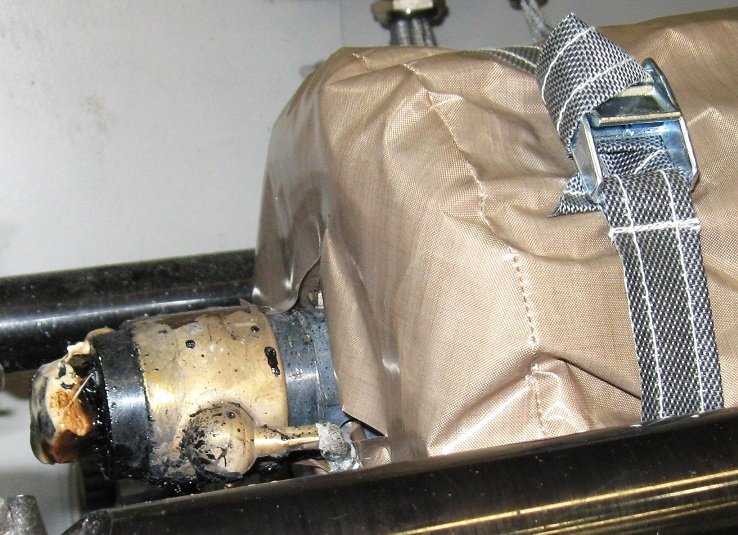

To reduce the cost for power consumption, we offer an installation of thermal insulation covers on heated parts of your machines.