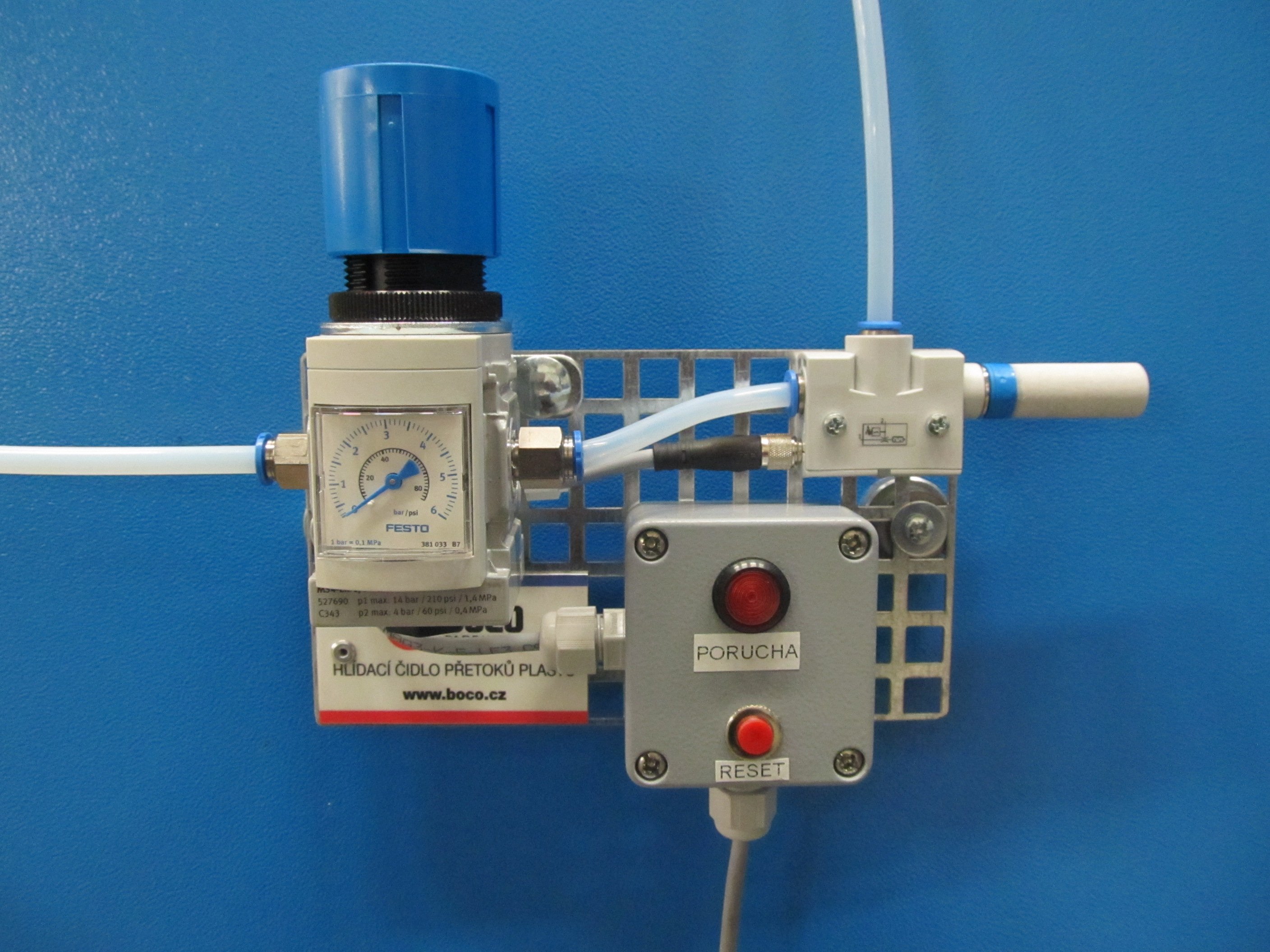

e.g. on the injection moulding nozzle, mould inlets, etc.

In common production of plastic parts on injection moulding machines leakage occurs between the injection moulding unit and the mould resulting in plastic material leakage. The plastic can go along the nozzle all the way down to the heating belt and cover even the entire length of the barrel and all heating belts and cause significant problems and damage.